-

-

Mon - Fri 7:30 - 17:30

-

Hasanağa OSB Mh. 5. Cd. No:6 Nilüfer/BURSA 16280

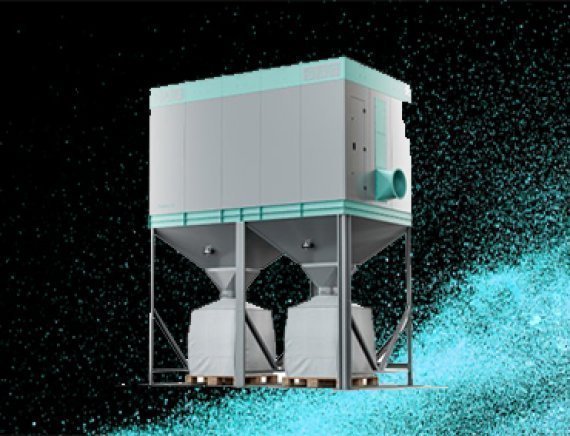

Dust Collection Silo Benefits

Dust Collection Silo Benefits

A dust collection silo becomes valuable when dust generation is high and handling frequency becomes a bottleneck. Instead of frequent container changes, dust can be accumulated in a larger storage volume with controlled discharge. This improves uptime, keeps areas cleaner, and reduces operator exposure.

The most important requirement is sealed transfer. Dust should move from the collector hopper to the silo through tight connections, airlocks, and appropriate valves to avoid leaks and airflow disturbances. The silo hopper design should support consistent flow and prevent bridging, especially with cohesive dust. Vent filtration during filling prevents emissions and maintains site cleanliness.

Level monitoring and alarms help prevent overflow. Discharge can be handled via screw conveyors or other metering devices to match process needs. With correct engineering, a dust collection silo turns dust handling into a predictable, low-intervention operation.