-

-

Mon - Fri 7:30 - 17:30

-

Hasanağa OSB Mh. 5. Cd. No:6 Nilüfer/BURSA 16280

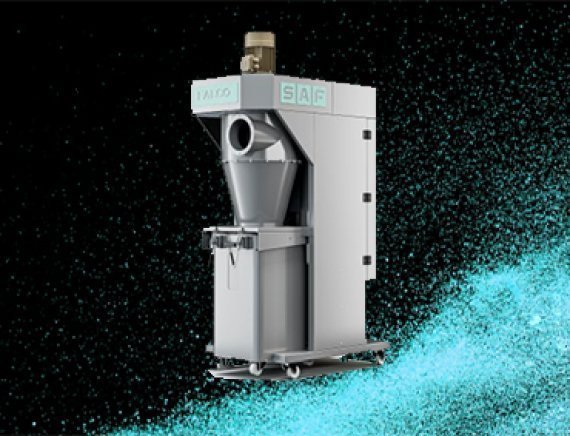

Dust Collector Applications

Dust Collector Applications

Dust collector applications vary widely across industries, but the goals remain consistent: capture dust at the source, protect workers, reduce contamination, and keep production stable. In operations like grinding, cutting, mixing, filling, and packaging, airborne particulate can accumulate quickly and create both quality and safety challenges. A dust collector should be engineered as part of the process, not added as an afterthought.

A strong application starts with effective source capture. Hoods, enclosures, and pickup placement determine whether dust enters the ductwork or escapes into the workspace. Duct design then maintains transport velocity and reduces pressure losses. Balanced branches and airtight connections are key to consistent capture across multiple machines.

Filtration must match dust characteristics. Fine powders, abrasive particles, and cohesive dust behave differently on filter media. Pulse jet cleaning settings should be optimized to maintain stable differential pressure, preserving airflow while protecting filter life. Discharge and storage also matter: sealed systems, rotary valves, screw conveyors, and containers or silos prevent re-entrainment.

By focusing on capture, transport, filtration, and discharge as a complete chain, plants achieve cleaner air, reduced downtime, and more predictable operating costs.