-

-

Mon - Fri 7:30 - 17:30

-

Hasanağa OSB Mh. 5. Cd. No:6 Nilüfer/BURSA 16280

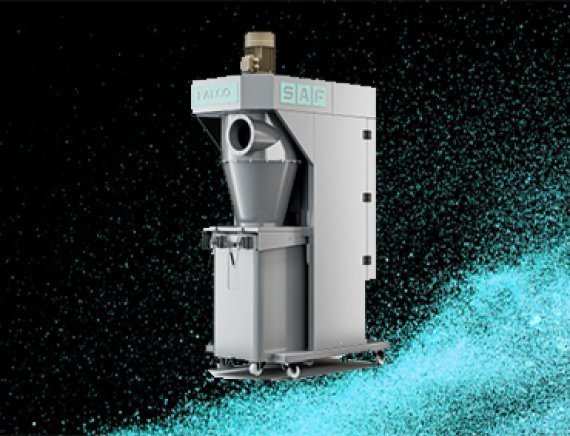

Dust extractor setup for cleaner workshops safer air and stable production flow

Dust extractor setup for cleaner workshops safer air and stable production flow

A dust extractor is a key part of process control not just housekeeping. Fine dust from cutting grinding sanding and material transfer can quickly spread across the workspace and impact operators equipment and product quality. The most effective approach is source capture supported by correct ducting and filtration.

What to size first

-

Number of sources and simultaneous operation

-

Dust type fine abrasive sticky or fibrous

-

Capture requirements and total airflow

-

Duct length fittings and real static pressure

Why performance drops over time

Many systems are sized only by airflow while ignoring pressure losses and filter loading. As pressure drop rises capture at the hood weakens which causes dust to escape even if the fan is running.

Build a reliable system

Use well placed hoods stable duct velocities and filtration matched to your dust behavior. Saf Teknik oriented projects focus on long term stability through realistic pressure calculations and practical maintenance planning.