-

-

Mon - Fri 7:30 - 17:30

-

Hasanağa OSB Mh. 5. Cd. No:6 Nilüfer/BURSA 16280

Silo Systems Planning

Silo Systems Planning

Silo systems planning requires balancing capacity, flow reliability, and site constraints. The “right size” is not just about tons; it must reflect consumption rate, delivery schedule, and available footprint. Material properties such as cohesion, moisture, and abrasiveness strongly influence hopper angle, outlet size, and whether flow aids are required.

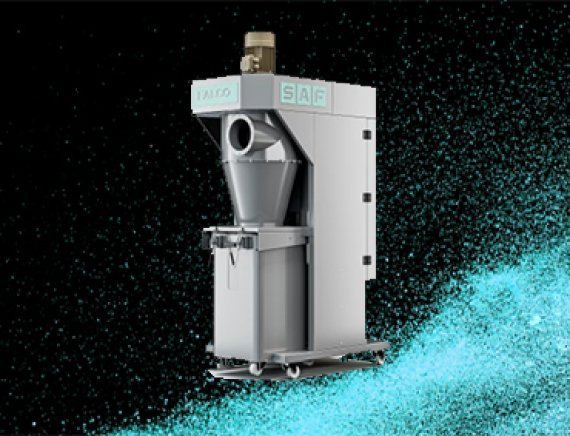

Filling operations can produce dust and pressure changes. Vent filters and appropriate filling arrangements control emissions and protect equipment. Instrumentation — level sensors, load cells, and alarms — improves inventory visibility and prevents overflow. Discharge systems can range from screw conveyors to pneumatic conveying or dosing units depending on process control needs.

Safety and maintenance access should be designed in from the start. A well-planned silo system reduces stoppages, improves throughput stability, and supports cleaner site operations.